Water deluge systems are a critical quality assurance measure for vehicle manufacturers seeking to test for and ensure that vehicles are leak proof under a range of environmental conditions. While a critical part of the vehicle manufacturing process, each deluge system application is different, and it is important to consider your specific needs to ensure that yours is fit for purpose.

Some considerations include:

- Water efficiency and management

By their nature, deluge systems use enormous amounts of water which, of itself, is an expensive input. Further, the management of wastewater produced through the deluge system needs to be considered and factored into the design and management of the facility.

- Vehicle type and system configuration

Every vehicle is a different size. Think planes, trains and automobiles! And the way in which a vehicle enters a deluge system will vary widely as well (for example, a train requires rails). This variation has considerable implications for the design, configuration and function of the deluge system.

- Level of automation required

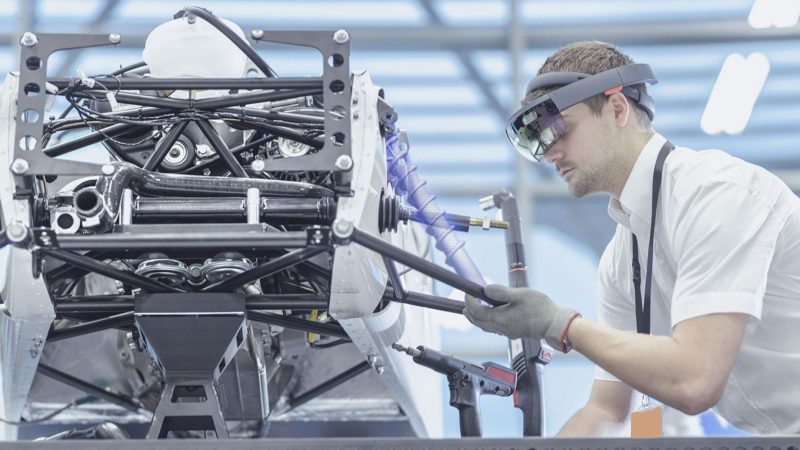

Automation and the application of contemporary technology is a highly effective way to ensure quality control, minimise input costs and integrate with other parts of the manufacturing process flow. Automation design and integration capability needs to be factored into the design of any deluge system.

- Facility design and process flow

Finally, the overall design of the processing facility and the manufacturing process flows will have important implications for the design, location and function of a vehicle deluge system.

DRYSYS specialises in the design, integration, manufacture and installation of vehicle deluge systems. We provide bespoke water deluge test facilities in a number of different formats including drive through arrangements, traversing gantry (roll over), PLC controlled with HMI interface, water treatment side systems and more.

Each deluge test facility is custom designed and built by DRYSYS to suit the specific testing criteria required. The testing facilities are generally incorporated into production or testing lines and drench the vehicle with water, at a set flowrate and pressure, to certify each vehicle meets the build criteria.

Our water deluge systems can be designed to suit any type or shape vehicle. They can also be provided in a number of different formats such as:

- traversing gantry (roll over)

- drive through arrangements

- in or above ground water storage tanks

- PLC controlled with HMI interface

- re-cycled and recirculated water

- water treatment side systems

The deluge facility is controlled by a PLC programmed to control the entire facility and monitors the test criteria, which includes water flow rates, water pressure, time and travel speeds in traversing models.

At DRYSYS our bespoke personalised service means we are here to help from beginning to end. We work in close collaboration with your team, from conceptualising and designing, to testing and commissioning and after sale services. We pride ourselves in not only being a leading vehicle water deluge test facility design and construction, but in providing custom facilities that are specifically suited to the individual needs of our clients.