Gear is an important part of any machinery. From a tiny clock to car gears form an integral part of various machines and perform various tasks like reversing the direction of rotation, altering the angular orientation, convert rotary motion into linear motion, and so on. These motions accelerate the machine’s working.

Therefore, gears need to be in good shape to perform their work efficiently and last long doing what they do. Therefore, these gears have to be Impeccable in quality, enter the gear shaping tools.

Gear shaping is used in making the gears or precisely the teeth on the gears.

There are mainly two ways of shaping gears:

- Gear generating: It is a process of cutting the gear through continuous rotation over a long time.

- Gear form cutting: It involves the use of tools that give the desired shape to the gear,it’s relatively a faster process.

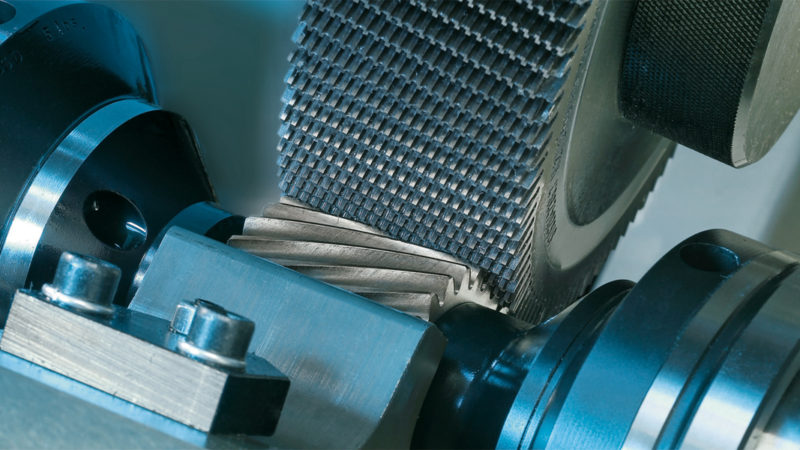

Sub categorically gear cutting is divided into hobbing, shaping. These processes are of longer span and thus durability of the shaping tool plays a major part.

Sub categorically gear form cutting is divided in broaching, milling, gashing,

For all of the above processes gear shaping tools are required, some of them are as follows:

- Gear shaper cutters– They are disc-type in design for producing splines, etc. The gearing and shaping tool rotates together and this process is called shaping, long hours of rotating and friction give the gear the desired shape. They too can be acquired in customized sizes according to one’s needs.

- Gear hobs- These are the major tools used in the process of hobbing. Hobbing is the most common process to create gear teeth by using the force of rotation aided by a fluid. Hobs come in a different pitch, length, bore according to the needs of the company.

- Gear shaving cutters- They are gear finishing tools and are therefore made with high precision they are the fastest way of shaping a gear.

- Form milling cutters- They are used in the process of milling which involves the use of rotatory cutters and is used in worm cutting, rack cutting, and so on.

There are many more ways to shape gears like- bevel gear cutting machine. These gears are crafted by trained, experienced engineers and are sold after multiple levels of checks regarding precision, blade size, design, etc.

Apart from the good quality of tools, their regular servicing is also important as it is their natural characteristic to wear and tear with time, thus servicing not only increases the life of tool but also the efficiency of the tools.

Some popular services offered are

- Re grinding- In simple word re sharping the tools as with extensive use of the tool it may become blunt and carry the work with 100 percent precision regrinding becomes necessary. Any tool mentioned above can be re-ground as per one’s preferences.

- PVD coating- It is also known as physical vapor deposition coating, a wide variety of materials are used for coating. Usually, a material with good heat resistance is chosen for example: tin alcrona, etc. These coatings make their surfaces hard and increase their life.