When one talks about molds, the first thing to strike his mind is the parts that are used to make different articles by processes as blow molding/injecting molding. The parts or what is termed as mold is actually a hollowed-out piece that is filled by liquified raw material which hardens and sets, adopting the same shape as of mold. It is used to produce objects like wire spools, bottle caps, automotive parts and components, toys, plastic chairs and tables, mechanical gears and almost all the other plastic products available in the market. These molds are used for many purposes by many industries of different fields.

What is the mold?

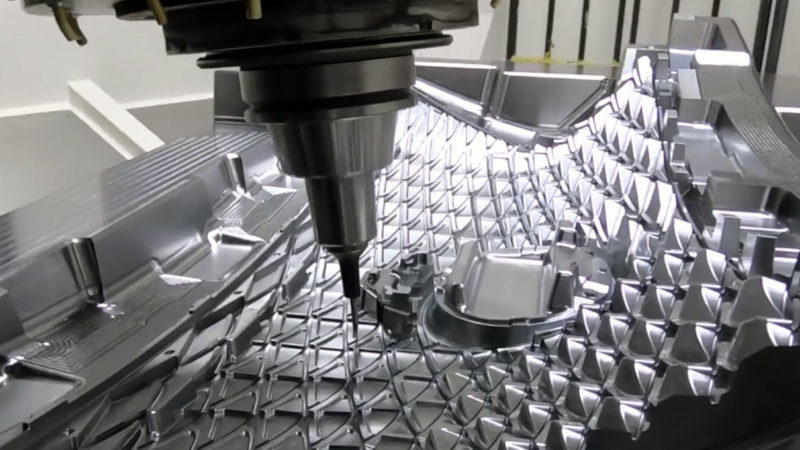

Mold is a hollowed-out block that is used to set the shape for a product being produced. The raw material used depends on what the product is going to be used for. It can be made of many different materials, however, most commonly used raw materials are aluminum, plastic, copper, steel, alloys, etc. The mold is supposed to be made perfect as they are extremely critical in the manufacturing process of a product. As molds shapes are the final product, it is always crucial to use the correct mold.

A mold maker the manufacturer of molds. The mold maker is the most important aspect of mold manufacturing, as the outcome of his works will determine the outcome of mold shape which in turn will determine the shape of the product being produced. For better results, one should be have thorough knowledge of the processes used. In the current world, most of the household items we use are molded. It is also used to manufacture the everybody’s favorite LEGOs. Not only this using molds to manufacture goods increases productivity, cuts down expenses, gives the ability to produce premium quality products at much higher output rates with higher efficiency and at cost-efficiency.

Types of molding

There are quite a few types of methods that are being used for molding. Some of them are –

- Injection Molding

- Blow Molding

- Powder Molding

- Compression Molding

- Thermoforming

- Matrix Molding

- Spin Casting

- Extrusion Molding

Injection Molding

The most simple, widely used injection molding, self-explanatory is process of manufacturing parts by injecting molten raw material in the mold. It is done with different materials like metals, glasses, and most commonly for thermosetting and thermoplastic polymers. Once poured in the mold the materials sets in the shape of the mold and one obtains product of desired shape. The parts or what is termed as mold is actually a hollowed out piece that is filled by liquified raw material which hardens and sets, adopting the same shape as of mold.These molds are used for many purposes by many industries of different fields.

Blow Molding

Blow Molding is a manufacturing process which is used to produce hollow plastic parts, which if needed can be joined later to make other products. The basic concept behind it is to start to melt the plastic into semi solid state and then put it in the mold and then blow air in mold to push it to take the shape of mold, which later when cooled, is taken out of the mold.

What is Mold Manufacturing used for?

In our daily life, we always encounter goods that are produced by mold manufacturing. It is used to produce objects like wire spools, bottle caps, automotive parts and components, toys, plastic chairs and tables, mechanical gears and almost all the other plastic products available in the market. It is also used to manufacture the everybody’s favorite LEGOs. Not only this using molds to manufacture goods increases productivity, cuts down expenses, gives the ability to produce premium quality products at much higher output rates with higher efficiency and at cost-efficiency.